From Idea to Reality: This Is How We Work

We often encounter clients who have a brilliant idea or a terribly annoying problem, but simply don't know how to get started with the implementation. They fear that engineers will throw around incomprehensible jargon, the process will be opaque, and in the end, the bill will be double what was agreed upon.

Let's forget this stereotype.

We at Design of Brothers Engineering Ltd. believe that good engineering work is not black magic, but a logical, transparent, and understandable process for everyone. No secrets, no obfuscation. In this post, we'll show you step-by-step how we work, from the first phone call to the delivery of the finished product. Casually, honestly, as befits good engineers.

Step 1: The First Date – When We Meet the Idea

Everything starts with a conversation. You contact us because you have an idea, say, a new innovation, or you have a problem, for example, a process in your plant is slow and needs to be automated. The very first step is a completely free consultation of about 1-2 hours.

The goal of this is not to sell you something. The goal is to understand what your real objective is, or what the problem that truly hurts is. We also ask the seemingly stupid questions because the engineer's brain is already clicking away at potential pitfalls and solutions. There's no talk of quotes or deadlines yet. There's only the problem, and us, looking for the solution.

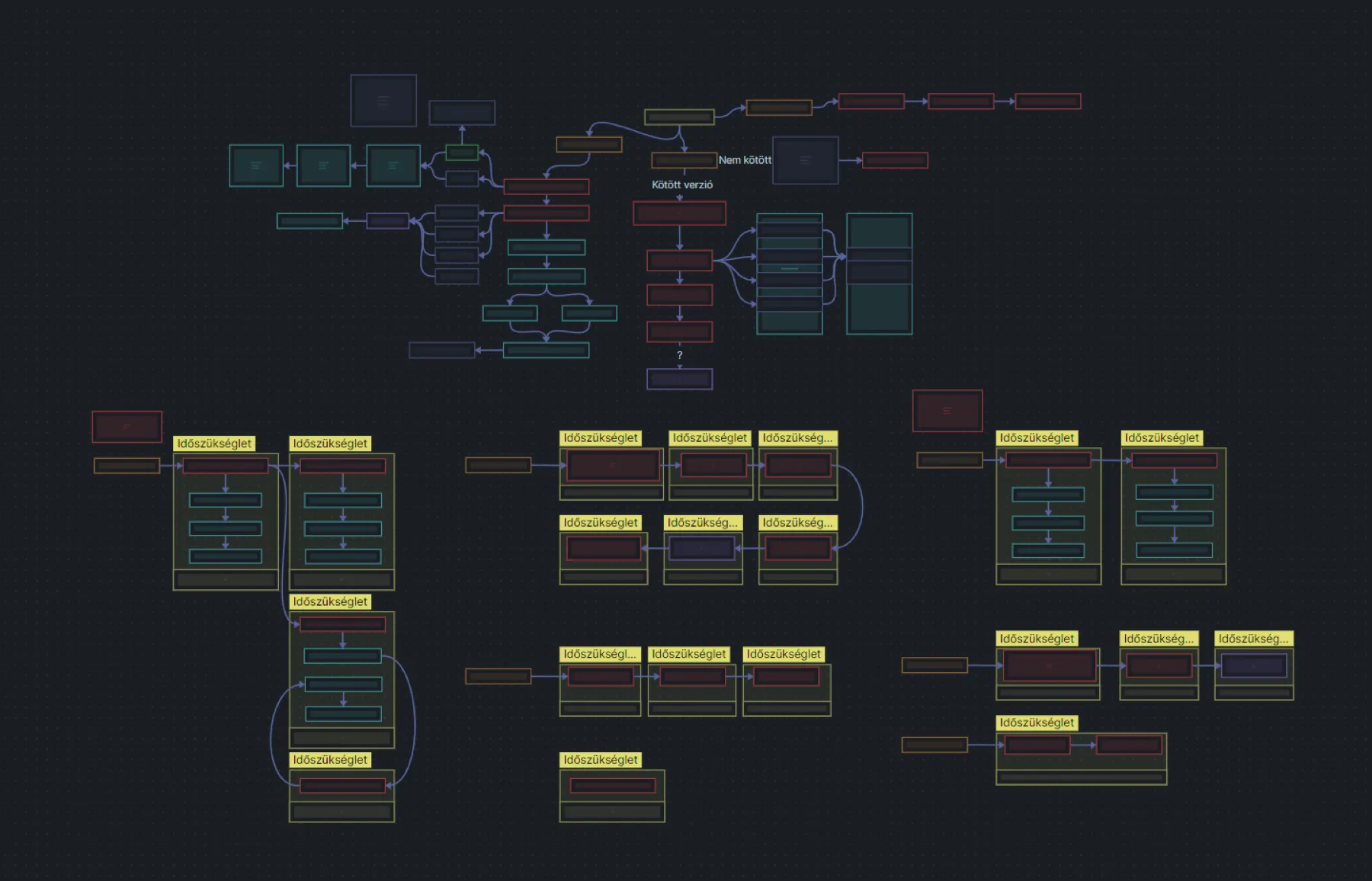

Step 2: Mind Map and Roadmap – From Chaos to Order

If, after our conversation, we see that we can help, and you also feel you're in the right place, then comes one of our most important internal processes. Before we draw a single line in CAD, we sit down and create a Mind Map.

This is the phase of creative chaos. We sketch out every possible solution, dead end, material quality, technology. "What if it's made of steel? And what if it's aluminum? Does it need welding? Could it be bolted instead?" We consider everything so that there are no surprises in the end, or at least as few as possible.

When the picture is clear based on the Mind Map as to which is the most viable path, we create a Roadmap from it. This is no longer a brainstorming session, but a rock-solid plan. We precisely define the goals, and just as importantly: the NON-goals. So we also record what the project will not deal with. This is the best antidote to later misunderstandings. This Roadmap also includes an estimated timeline, as the processes need to be understood chronologically as well.

Step 3: The Contract – The Foundation of Our Work Together

The human brain has a strange characteristic that science calls cognitive bias. After a few weeks or months, everyone remembers what was discussed a little differently. "I thought...", "But we agreed that...". Sound familiar? The simplest example of cognitive bias is our bicycle example, which we always tell when this topic comes up. Let's say I tell someone that I like to ride a bike. The receiving party, to process the information more "efficiently," creates associations, such as that I like cycling and that I have a bike, even though I didn't say a single word about the latter. I might cycle just because I need to exercise for a healthy lifestyle, or I never said I own a bike, maybe I rent one or borrow someone else's.

Well, things like that are why we humans experience someone talking nonsense. We avoid this with a very simple tool: the contract.

Based on the Roadmap, we prepare a detailed contract that contains the tasks, milestones, deadlines, and costs in black and white. This isn't mistrust; on the contrary, it's the basis of a clear and fair partnership. It protects both parties. We know exactly what we have to deliver, and you know exactly what you will get for your money. We don't lift a finger without a contract. Seriously.

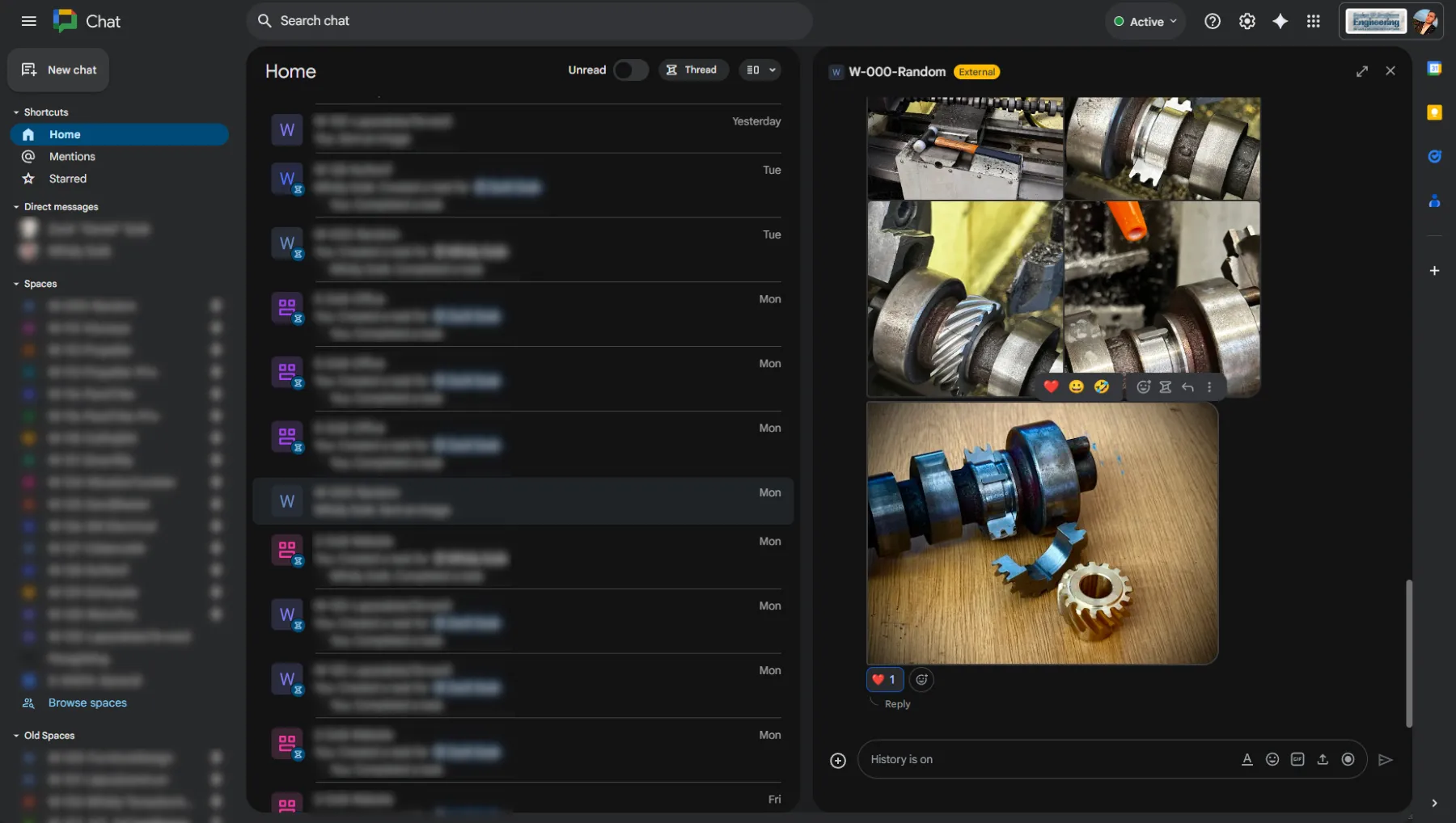

Step 4: The Engine Starts – Design and Continuous Communication

Once the paperwork is in order, the real work begins. We fire up the design software and start transforming the concept into tangible, 3D models. If the nature of the project requires it, we create multiple design versions, and we choose the winner together. After all, you have to like it and it has to solve your problem.

We don't disappear for weeks during the work. Continuous communication is our other superpower. For larger projects, we create a dedicated Google Chat group where we can coordinate almost instantly. In addition, of course, there are phone calls, emails, and regular online or in-person meetings. You will know about every step.

Financing is also aligned with this. For smaller design jobs under 20 hours, you generally pay afterward. For larger projects, we tie payments to milestones. And if there's manufacturing involved, we ask for half of the manufacturing cost upfront after the design fee is settled. This is completely understandable: we also have to buy the materials and tools. It's a fair deal.

Step 5: "Oops, That Didn't Work Out!" – Problem Solving and Changes

Our slogan is "We have a solution for everything". This wasn't just made up by marketers; we really mean it. Of course, unexpected situations occur in engineering work. A part doesn't behave as the simulation predicted, or a supplier is late. In 99% of cases, we solve these problems, even at our own expense, because it's our responsibility to ensure the final result is perfect, and the client is satisfied and happy.

What is the toughest nut to crack, however, is when the client changes their mind in the middle of the project and wants to go in a completely different direction. This is exactly why the contract exists. If a change is needed, no problem, we are flexible. We sit down, discuss it, prepare a contract amendment (which, of course, also affects costs and deadlines), and after settling the work done so far, we move forward in the new direction. This is fair to everyone.

Step 6: The Finish Line – Handover and Support

Our work doesn't end with sending a ZIP file with the designs. If we also manufactured the product, we hand it over tested and commissioned. If we only supplied the designs, we still stand by you: we provide manufacturing support, help you choose the right contractor, and answer your questions.

We think like a general contractor: we can take a project from thought to shelf. This is our real strength. Design, manufacturing, and even the creation of marketing materials (visualizations, graphics) are on our table.

Our goal is not just for you to receive a product or a design, but a working, reliable solution that you will be satisfied with in the long run. Because in the end, that's all that matters. The rest is just unnecessary fluff.