Our Machinery

Discover our machines, with which we meet the highest quality expectations.

TCFM-100 CNC Milling Machine

Refurbished, high-performance milling machine with thousandth-of-a-millimeter accuracy. For the production of complex metal and plastic parts.

Technical Details

The TCFM-100 is a long-established, robustly built 3D horizontal milling machine, a blend of classic reliability and modern precision. A legendary machine that has undergone a complete refurbishment. The original structure, manufactured in 1982, has been equipped with a modern, high-knowledge NCT controller. Thanks to the renovation, the equipment ensures thousandth-of-a-millimeter accuracy and efficiency. A reliable partner for carrying out custom and series production tasks.

TCFM-100 CNC Lathe

Another refurbished, high-performance machine with thousandth-of-a-millimeter accuracy. For the production of rotationally symmetric parts.

Technical Details

The machine's real specialty lies in its horizontal main spindle, which provides unparalleled flexibility. The design allows us to mount both a tool holder (for milling) and a workpiece chuck (for turning) in the main spindle. Thanks to this, we can tool both of our machines as we wish: set up for milling or turning. This versatility makes the TCFM-100 an ideal choice for the efficient production of complex parts requiring multiple types of machining.

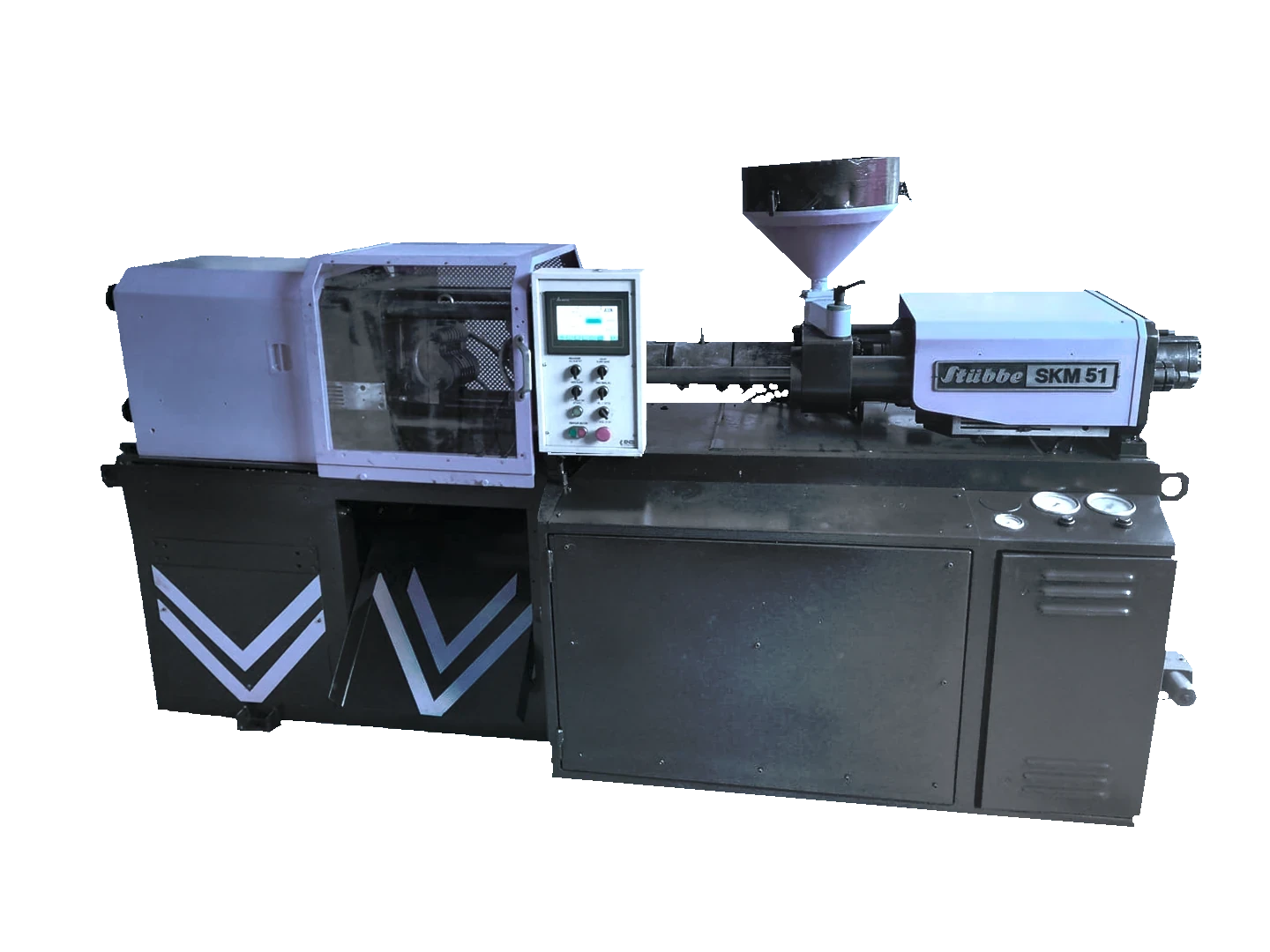

Stübbe SKM 51 Injection Molding Machine

Fully refurbished injection molding machine for high-volume production, with 51 tons of clamping force and a shot weight of 82 grams.

Technical Details

With our automatic injection molding machine, we undertake the high-volume production of plastic products. We oversee the entire process from tool design and manufacturing to quality control, ensuring consistent quality and cost-effective production. Our machine is capable of 510 kN of clamping force, with which we can produce parts with a maximum injection molding part weight of 82 grams, up to a maximum size of 280x280 mm.

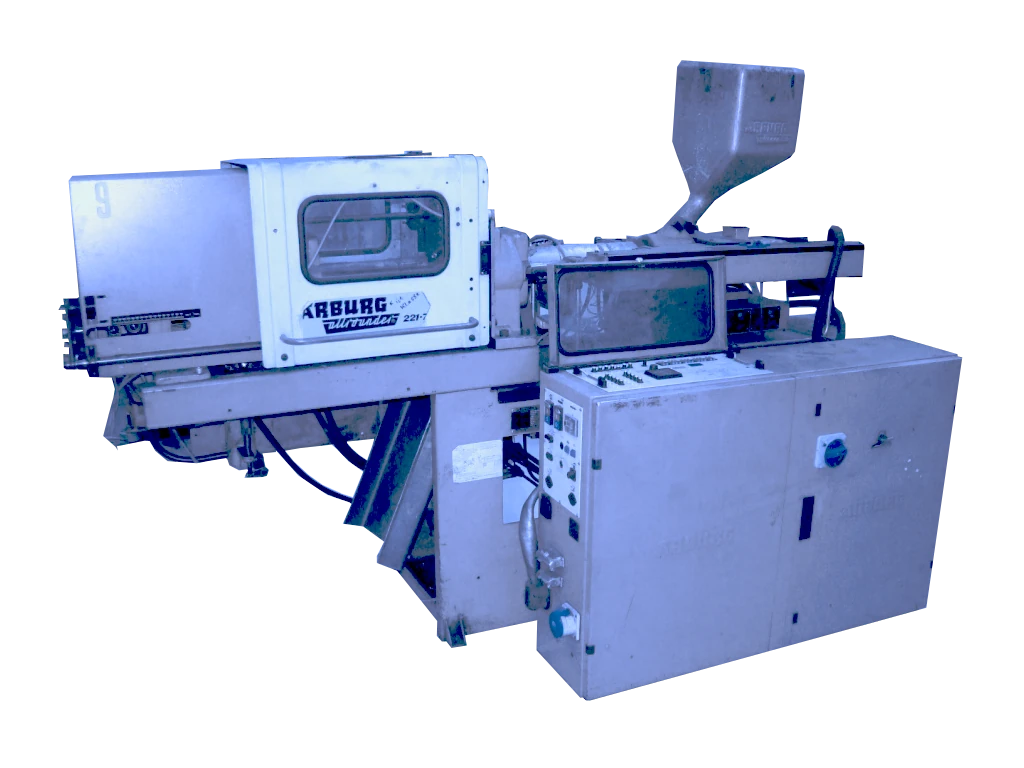

Arburg Allrounder 221U

Fully refurbished injection molding machine for high-volume production, with 25 tons of clamping force and a shot weight of 38 grams.

Technical Details

With our automatic injection molding machine, we undertake the high-volume production of plastic products. We oversee the entire process from tool design and manufacturing to quality control, ensuring consistent quality and cost-effective production. Our machine is capable of 250 kN of clamping force, with which we can produce parts with a maximum injection molding part weight of 38 grams, up to a maximum size of 250x250 mm.

Bensonic 902 bw-1522p Ultrasonic Plastic Welding Machine

For ultrasonic welding of plastic parts at a frequency of 15 kHz.

Technical Details

With the ultrasonic plastic welding machine, a bond can be created between thermoplastic parts quickly and efficiently without the use of adhesives, screws, or solvents. The technology uses high-frequency ultrasonic vibrations that generate frictional heat at the contact surface of the plastic parts. This heat melts the plastic, and under pressure, creates a homogeneous, leak-proof, and strong bond. The welding takes place in seconds, making it ideal for mass production.

Vibratory Finishing Machine

Self-designed and manufactured, U-section, vibratory principle finishing equipment, with a 1.1 kW vibromotor.

Technical Details

With our finishing machine, we undertake the cleaning, deburring, surface treatment, and polishing of small and medium-sized parts. The U-shaped container vibrates the abrasive media inside with the help of a vibromotor. Due to the vibrations, the abrasive bodies and the parts rub against each other, resulting in surface treatment. The process is uniform and automated, which ensures consistent quality. Maximum workpiece size: 250x250 mm.

CNC Flatbed and Tube Laser Cutting

For cutting steel, stainless steel, aluminum sheets, and hollow sections.

Technical Details

With our nearby supplier's industrial laser cutting machine, we undertake the cutting of steel, stainless steel, and aluminum sheets up to 12 mm thick, and hollow sections up to a diameter of 200 mm, with a maximum placeable sheet size of 1500 x 3000 mm. The laser cutter is an industrial machine that operates with a fiber laser, which is the industrial standard for cutting metals. For sheet cutting, we can use any image or vector file; for non-vector graphic files, file conversion is necessary.

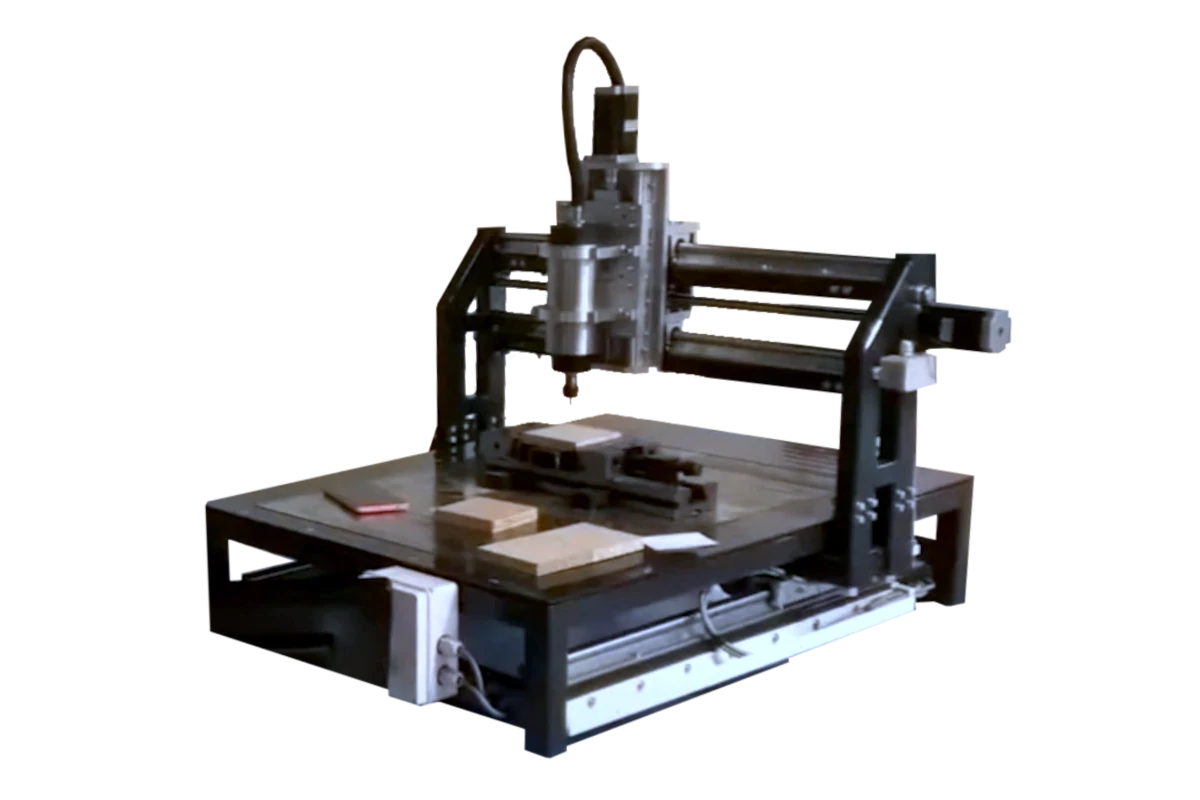

CNC Gantry Milling Machine

Self-designed and manufactured milling machine with a large working area and vacuum table.

Technical Details

The machine can be used for milling and engraving large-sized wood, plastics, and metals. The machining area is 640x520x140 mm, and the clamping of workpieces is assisted by a built-in vacuum table. Control is provided by the reliable, industrially stable LinuxCNC software. This CNC milling machine is the first machine we designed and manufactured, back in our high school days, at the ages of 15 and 18, almost 10 years ago in 2017.

Anycubic M3 Max SLA 3D Printer

Printing large 3D models from standard and ABS-like plastic resin.

Technical Details

The Anycubic Photon M3 Max features a large 7K resolution monochrome display and a 14.7-liter build volume with 46-micron accuracy. The printer is capable of an average printing speed of 60 mm/hour, which is good for its large print size, allowing for the relatively fast creation of large objects. It is an ideal 3D printer for the professional and hobby-level printing of large plastic parts. Maximum printing dimensions: 300 x 298 x 164 mm.

Anycubic M5s Pro SLA 3D Printer

Printing medium-sized 3D models from standard and ABS-like plastic resin.

Technical Details

The Anycubic Photon M5s Pro, with its 10.1-inch, 14K monochrome resolution display, allows for a printing accuracy of 17-25 microns. The printer is capable of an average printing speed of 70 mm/hour, but can reach up to 105 mm/hour with Anycubic's high-speed resin, making it ideal for rapid prototyping. Another advantage is that the printer does not require manual leveling, as it has automatic leveling, making work easier. Maximum printing dimensions: 200 x 224 x 126 mm.

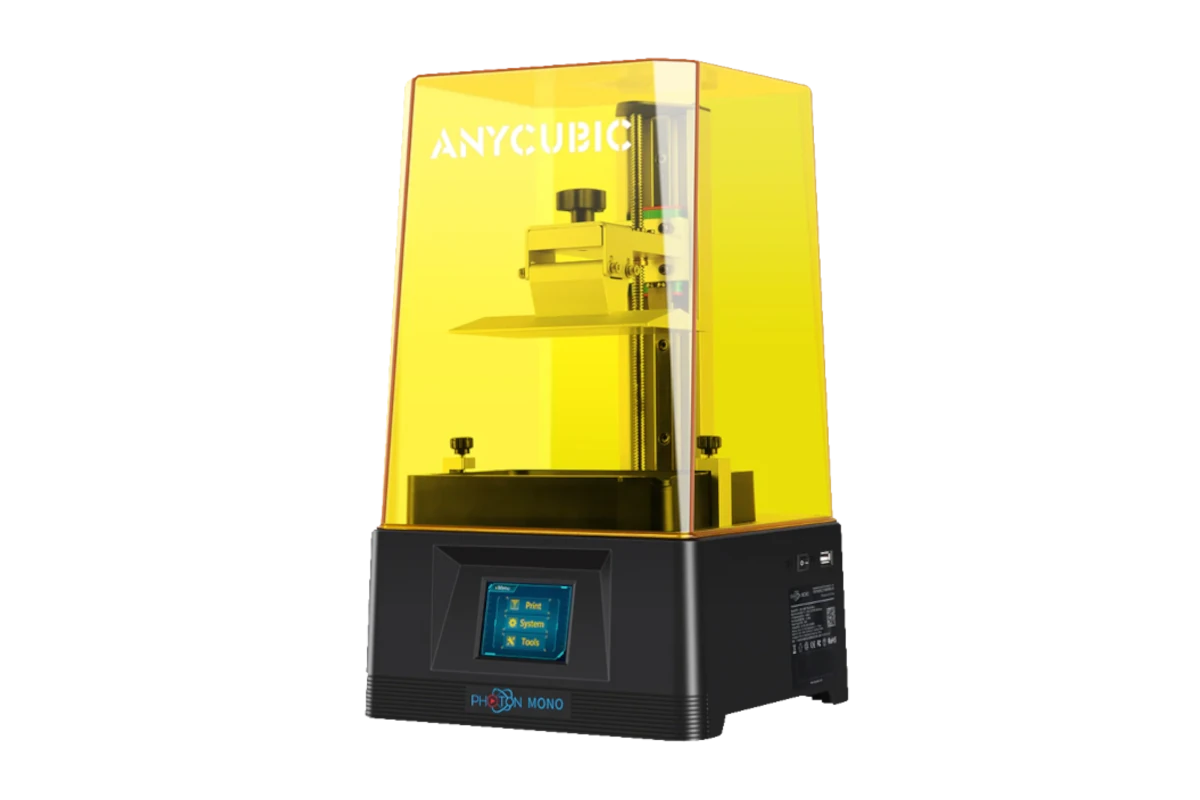

Anycubic Photon Mono 4K SLA 3D Printer

Printing smaller 3D models from standard and ABS-like plastic resin.

Technical Details

The Anycubic Photon Mono 4K, with its classic 6-inch, 4K resolution monochrome display, allows for a printing accuracy of 35 microns. The printer is capable of an average printing speed of 50 mm/hour. It is an entry-level 3D printer with which we can print smaller parts. Maximum printing dimensions: 165 x 130 x 80 mm.

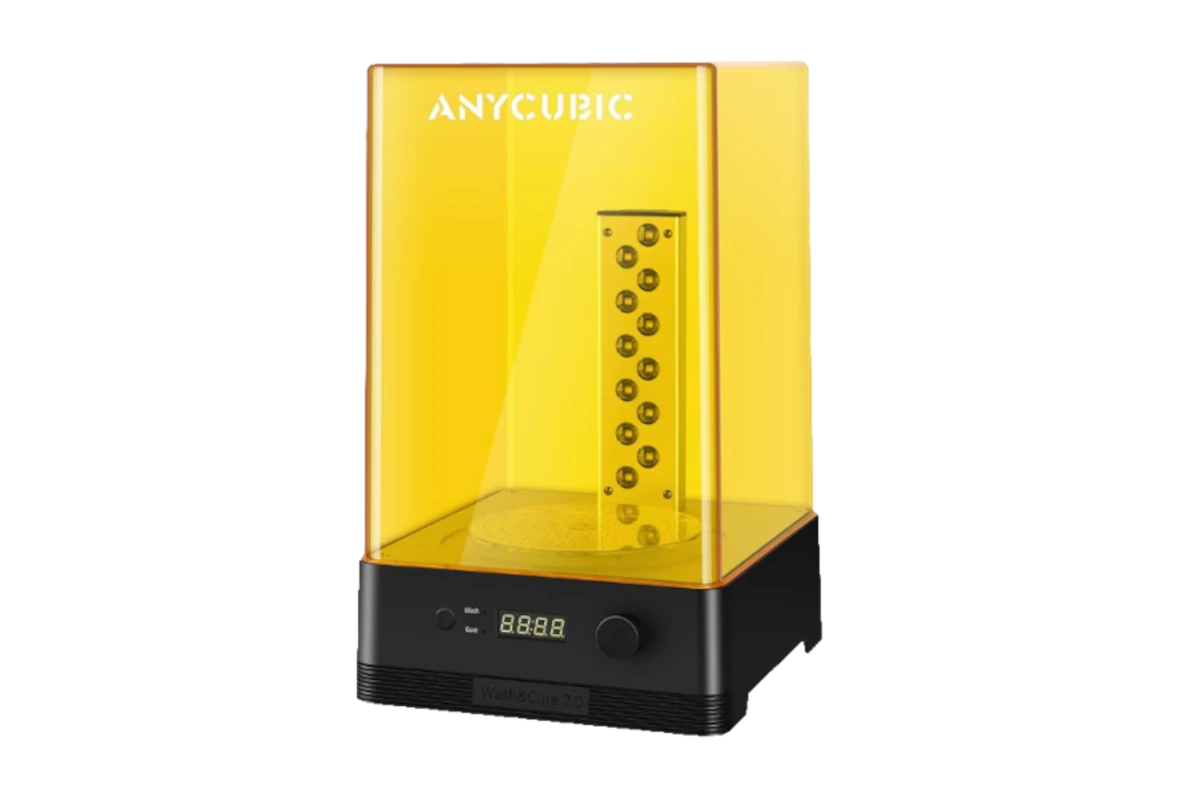

Anycubic Cure & Wash Machine Plus Part Washer

For washing and surface finishing our 3D printed parts.

Technical Details

After finishing the printing of 3D printed parts, it is necessary to thoroughly remove the excess resin, which is taken care of by the washing machine's cleaning vortex in the machine's large, 6-liter tank. After washing, the parts must be post-cured to achieve maximum strength and hardness, eliminate any sticky surface, and remain dimensionally accurate and durable, thus preserving their shape. Maximum size 192 x 120 x 290 mm.